Product Sheet

Description / Price

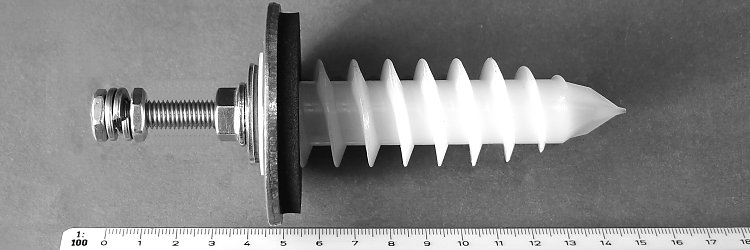

Stainless steel anchor AISI 304 (316), A2 (A4), with two flat hex nuts and spring washers for fastening trellis cross bars on both sides, M8 shaft, flange nut, bonded washer, large cover plate d=60 mm for the borehole closure, weather proof foam seal, integrated threaded-nylon-dowel.

>>> Price

Usage

An inexpensive way to attach wooden trellis on insulation from 10 cm layer thickness. For rigid foam, polystyrene ("Styrofoam"), soft wood fiber boards, etc. Not suitable for mineral wool and other flaky or bulked insulating materials. Without cutting the facade. Does not form a thermal bridge! However, only for low to medium loads. Wall distance 20 mm, the actual distance from the wall is calculated from the wall gap and the sum of the screwed cross-sections and can be up to 60 mm for lath thicknesses of approx. 20/20 mm. Please also use the tips for the step sequence in planning and execution of wooden trellis and for optimal trellis attachment.

Recommended Tools

For pre-drilling (8-12 mm) hammer drill bit HB 44444. Alternatively, concrete drill bit, inexpensive stone drill bit, or universal drill bit. For the second drilling, hammer drill bit HB 16160.

Installation

With a drill d = 8 - 12 mm, just pre-drill a bit (Fig. 02) to pierce the plaster layer, then drill with a drill d = 16 mm approx. 15 - 25 mm deep and without hammer blow to create a straight guide for the dowel shaft. For soft wood fiber boards and Heraklith-boards: Here, the 16 mm hole is made to a depth of approx. 90 mm. Then grasp the point holder with a 13 mm open-end wrench on the flange nut and carefully screw in (palms with working glove - Fig. 03) until the thread engages and it is aligned vertically and horizontally. Then continue to screw in the point holder, constantly checking the vertical and horizontal alignment and, if necessary, correcting by pressing on the side. It is turned until the resistance increases significantly and the foam gasket is pressed together (Fig. 04). The large cover disc must have quasi contact with the grain of the plaster through the seal in order to act as a pressure disc. Subsequently, the respective trellis spar is mounted between the two spring washers and flat nuts. If the spar is too thick, attach without spring washers, or countersink the borehole.

Origin

Our own production “Made in Germany”: Shaft from Lower Saxony, pressure disc from North Rhine-Westphalia, anchor-system from Bavaria, cover plate merchandise, foam seal from Thuringia, small parts from Far Easts