Product sheet

Description / Price

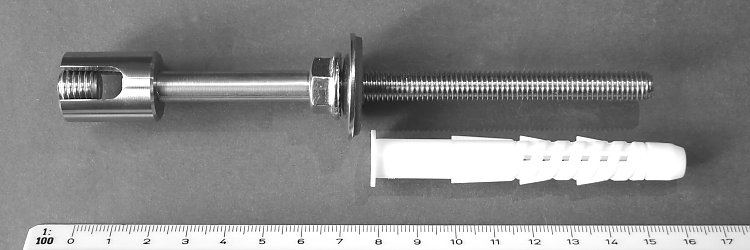

Made of high-grade stainless steel A4, 130 mm long smooth M8 shaft, with clamping head and M10 grub screw, hexagon flange nut, thrust washer with laminated seal and special rawl plug/anchor. The head is also available separately. >>>Price.

Use

Sophisticated fastening solution for stainless steel trellises with 8.0 mm wires. For light to medium loads. Distance to wall 60 mm. Can be used with almost all kinds of masonry and in construction panels that are at least 40 mm thick (for thinner panels, see below). Please also refer to the general tips on how to secure a trellis to a facade.

Recommended tools

To drill precise 10 mm holes for the wall plug, we recommend our hammer drill HB 44444 or our concrete drill, inexpensive masonry drill or universal drill; drill selection depends on wall type.

Asssembly

Remove the grub screw and keep it aside. Read the instructions on drilling and then drill a 10 mm hole approx. 10 cm deep. Insert the plug (do not use a plug in solid wood and pre-drill approx. 6 mm instead). The wall should be reasonably level to ensure optimum sealing (sand it down if necessary). Grease the shaft slightly and insert it into the hole, grip the flange nut with an open-ended wrench and screw it in. Align the grooves after you can't turn the mounts in any further with manual force. Once all fittings have been mounted, place the trellis in the grooves of the fittings, aligned and fixed with the grub screws.

Specifics

If you are working on a wall with exposed bricks (exposed masonry), you can position the fittings in the brick joints if they are at least 17.5 wide mm or more, but then without thrust washer and seal (photo 03). To remove the tightly fitting thrust washer, turn it several times in the direction of the flange nut in order to enlarge the sealing hole, then turn it in the other direction and remove.

If the wall is made of hollow bricks, pilot-drill a small hole before carefully drilling to 10 mm- both times without using percussion. If the plug nevertheless turns in the hole, drill the hole carefully to 12 mm and use a DL 12090 long plug (if you need it, we will deliver this plug without cost). Alternatively, drill the hole open to 16 mm and use a SD 16130 sieve-sleeve with bonding mortar to glue the fitting with the original white plug in the wall (if some mortar is now obstructing the plug, drill it open with a 6 mm bit).

A bolt-set is available for through-hole (push-through) mounting.

Origin

Fassadengrün's own production-- Made in Germany (Saxony): head from Saxony, shaft and disc from North Rhine-Westphalia, plugs from Baden-Württemberg, small parts are imported from Asia.