Product Sheet

Description / Price

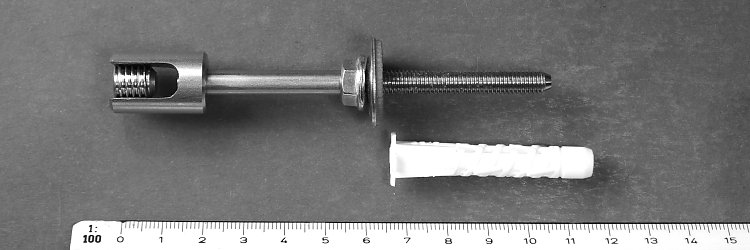

Made of stainless steel A2, 90 mm long smooth M8 shaft, with clamping head and M10 grub screw, hexagon flange nut, thrust washer with laminated seal and special rawl plug/anchor. The head is also available separately. >>>Price.

Application

Sophisticated fastening solution for stainless steel trellises with 8.0 mm wires. For light to medium loads. Distance to wall 60 mm. Can be used with almost all kinds of masonry and in construction panels that are at least 40 mm thick (for thinner panels, see below). Please also refer to the general tips on how to secure a trellis to a facade.

Recommended Tools

For accurately fitting rawlplug holes (8 mm): hammer drill HB 44444. Alternatively, for impact drilling: concrete drill, inexpensive masonry drill, or universal drill; selection also depends on wall type.

Mounting

If necessary, please refer to the guidelines we've provided on drilling and for using the enclosed special plug for metric threads; exceptions: see below. For a good seal, the surface should be reasonably level and flat or made so (sanded down). Drill hole (d = 8 mm, approx. 5 cm deep) should be brushed or blown out well, and if necessary (on light walls), the drilling dust simultaneously vacuumed off. In solid wood without plugs: pilot-drill (pre-drill) approx. 4 mm, front 5 mm. Do not use worn drills! With very hard surfaces, such as concrete and masonry (brick), you can widen the hole slightly in the front third by: holding the drill bit against the wall of the hole and turning it slightly, tilting it at the same time. Then also break or chamfer the outer edge of the drill hole with a larger drill bit at the front. Insert the rawl plug and lightly hammer it in; the four small white collar plates must come as close to the wall as possible. Then loosen grub screws and grease the shaft of the cross mount slightly; insert it into the rawl plug, press firmly and screw in under pressure first 2-3 turns until the mount engages ('grips' into) the plug. Then grasp the mount on the hex nut with a wrench and screw it deeper into the rawl plug until the seal is larger in diameter than the stainless steel disc.

Special Features

For special and wooden facades, (please refer to the linked instructions). Use a bolt set for through-hole mounting. For thin-walled concrete garages, rawl plugs (anchors) can be shortened 3-5 mm at the end by cutting off (pruning shears) or sawing off (hacksaw); the threaded shaft engages only 42 mm into the rawl plug.

Source

Production: Germany: head from Saxony, washer and shaft from North Rhine-Westphalia, plug from Baden-Wurttemberg; small portion from the Far East