Product sheet

Description / Price

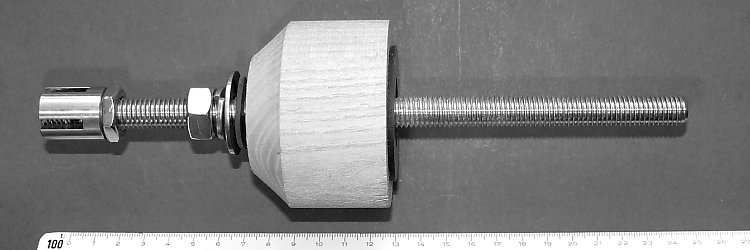

Cable mount with increased wall distance (12 cm), made of stainless steel, threaded shaft M12, crosshead d = 20 mm with grub screw, lock nut, adjusting nut, spring (lock) washer, washer (plate disk), cylindrical support console (formerly prismatic) made of decay-resistant ('rot-proof') Robinia hardwood, and press-ring/gasket. Wall console wood-coloured, natural white-gray patina after about 1-3 years of weathering. The head is also available separately. >>> Price

Use

Special mount for wire rope, 3 (and 4) mm formedium and heavy kits in accordance with the specifications of the respective wire rope system (if purchased as a pre-assembled kit). The distance from mount to mount should ideally not exceed 1.8 m at horizontal ropes and 2.2 m at vertical ropes. Simple or crosswise rope guidance. Wall distance approx. 12 cm. Mostly adhesive (glue) mounting; special case into outer insulation: see below. For support in choosing a trellis fitting, refer to our section on cable (cross) mounts.

Recommended Tools

Hammer drill HB 16210 for all drillings with or without sieve sleeves.

Installation

If necessary, refer to our instructions on drilling and the information on composite mortar. For optimal sealing, the surface should be reasonably flat or made so (sanded down). Drill 14 mm, depth approx. 11 cm. When using sieve rawl plug SD 16130, drill hole diameter 16 mm, depth 14 cm. Dismantle the cross mount console completely; also loosen the countered crosshead. Press in the composite mortar, insert the threaded shaft in a rotating manner; protrusion outside according to the wall distance (12 cm). If necessary, secure against sagging from below (photo). Spread or remove any mortar that swells out in order to create an almost smooth support for the seal. After setting, push on the wall console (support disc) together with all small parts, tighten adjusting nut firmly, fasten cross head with lock nut. Further installation carried out as described for heavy kits. A visible joint is formed around the pressed-on sealing ring which does not impair the function.

When mounting with metal anchors/plugs, DM 12030, please refer to the product sheet of that anchor; if necessary, you can shorten the threaded shaft, or let it be shortened by FassadenGrün. For installation into solid wood, request a shorter length if necessary. Drill diameter 10.5-11 mm. Grease threaded shaft, screw the two nuts on the shaft firmly against each other with 2 open-ended wrenches and then grasp the shaft at the nut further away with an open-ended wrench and screw it in directly. Then loosen the countered nuts against each other. By grinding in a short longitudinal groove at the end of the threaded shaft, it can act like a "self-tapping screw" facilitate screwing-in.

Special Features

The wooden wall consoles are suitable (without paint) for permanent outdoor use. Micro-cracks of approx. 0.1 - 0.3 mm breadth and 3 - 5 mm depth are not a defect and have no effect on function and sealing/insulation. With higher loads (hanging fruit, cold tension), the head may bend elastically 1 - 4 mm. This is not a defect; when the load is again reduced, the head goes back to its original position.

Origin

Made in Germany (Saxony), hardwood console from Saxony, hexagon nuts from the Far East.