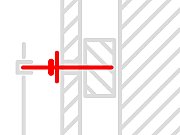

The fifth and at the same time the most optimal of eight variants, to attach growth aid technology to special facades is the inclusion of the substructure or load lathing to get a larger material cross-section for the attachment. In this case almost all standard kits can be used, details can be found below. The solution is very stable, but not so flexible, because it can only be attached along the axles of the inner wood lathing. If necessary, however, can be compacted with additional cables analogous to System 5050 (see photo).

Area of application

In this variant, the wood lath lying directly behind the outer skin is included in the fixture, the arrangement of the cables then often forms the course of the inner battens. In this variant material cross sections of 40 - 60 mm are generally available. The course of the inner wood lathing is mostly visible on the outside of nails, screws or clamps. If the luminaire is concealed (profile formwork), the lathing must be located by means of a search device or by a search drill. Alternatively, an outer 'doubling' is also possible to achieve a thicker cross-section. (See photos). In this way, significantly higher loads can be 'carried'.

Even with thicker or 'doubled' materials (eg claddings with the wall panel behind), where the thickness of the boards is at least 35 - 40 mm, variant 05 can be used.

Restrictions

In case of doubt, each drill point should be secured with four oblique test holes (left, right, top and bottom) of the smaller diameter so that the center of the wood batten beneath the formwork and not a sensitive edge area has been detected. It must not be drilled too tight, so that when the brackets are mounted, the inner woods do not split by too much spreading pressure. Furthermore, additional screw connections with HS 05060 may be useful in order to reinforce the bond of formwork and lathing in the region of the fastening points.

If a wind seal / steam barrier or a foil is to be expected directly behind an inner support lathing, brackets with correspondingly short shafts are to be selected whose threaded tips do not protrude from the support lath.

Easy construction style

The standard kits are almost always usable. In addition, all wall sockets with wood threads equal / smaller than 8 mm are suitable, which are screwed directly. All elements for nailing (staples, U nails, etc.) are also suitable.

Light construction style

[Translate to Englisch:] Die Standard-Bausätze sind verwendbar, sowohl ohne als auch mit beigelegten Dübeln. Im Zweifelsfall wird zunächst knapp gebohrt und eine Befestigung ohne Dübel versucht, misslingt dies, wird aufgebohrt, der Dübel gesteckt und darin befestigt.

Medium construction style

The 'Eco' and 'Premium' kits can be used with or without dowels, similar to the lightweight construction, see above. For higher loads, 'Classic' kits are used, with a material cross-section of less than 70 mm deviating from WM 10083 (also available as an eyelet, if required).

Heavy construction style

Concerns - mostly in uninsulated walls - even load-bearing, squared timber, so props, beams, etc. directly behind the outer formwork or the panel, stand material cross section of 70-120 mm available, can be attached to these places WM 12161. By way of derogation, but no 4 mm ropes, but those should be used with 3 or 2 mm.

Massive construction style

Analogous to heavy construction, massive standard kits with WM 12153 can also be installed under the conditions specified in the specifications.

Medium construction, evergreen honeysuckle

Wisteria and thus increased load: 'Classic' construction with WM 10083